Ion Sputter Coater - For your SEM

Category:

G10 applies vacuum environment inside of a chamber and coat (via gold deposition) the surface of a non conductive sample by Ion released from a Gold target, by plasma discharge at low-voltage.

The aim is to make conductive the surface of a sample which is non-conductive or has got weak conductivity, forming a metal thin film.

Platin (Pt) deposition is available too, and also electrode connection (conductivity increase test); both are also used as sample pre-treatment equipment for SEM.

Platin (Pt) deposition is available too, and also electrode connection (conductivity increase test); both are also used as sample pre-treatment equipment for SEM.

We can provide Ion Sputtering Coaters, an essential pre-treatment equipment for SEM samples; key feature are miniaturization, easy-to-use and budget price.

Videos

Component of Equipment

Ion Sputter Coater

- Tempered Glass for Chamber (Detachable)

- Ultra-light weight coater (10kg)

- Convenient service by BOARD composing for each function

Vacuum Pump - " Oil Rotary Pump " - optional

- Pumping Speed : 100L/min

Coating Material " Au or Pt "

- Au(4N) : 50mm(D)

- Pt(3N5) : 50mm(D)

- Gold target provided

Accessory - " Manual, Hose, Cable "

- Manual (Install/Quick Guide)

- Clamp

- 1.5M Vacuum Hose

- Power Cable

Functions

Button Description

- Power : Equipment’s Main Power Switch

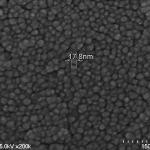

- LOW : 20sec Coating (Coating Thinkness : ±15nm)

- MEDIUM : 40sec Coating (Coating Thinkness : ±23nm)

- HIGH : 60sec Coating (Coating Thinkness : ±30nm) /li>

Coating Process

- Push the Power button, G10 model’s operatoin power supplying.

- User can choose among LOW, MEDIUM, HIGH mode and automatically make vacuum set and Ion Plasma sputtering within 2 minutes.

- After the coating, vacuum vented automatically and can check result.

Technical Features

- Automated Coating by one button click

- Fast and simple Coater: put the sample in the chamber and coat it just by pushing the Start Button

- Time of procedure completion: within 2 min. from start to Coating

- Set Coating conditions: 3 steps (20, 40, 60sec)

- 7 pieces of Sample Stub (Φ14㎜) mounting together in chamber

- Minimized installation space thanks to the compact size

Model | G10 |

|---|---|

Ion Current | 38mA (Fixed) |

Target Material | Au or Pt |

Chamber Size | 140mm(D) x 70mm(H) |

Sample Stage | 50mm(D) x 25mm(H) |

Target Size | 50mm(D) |

Sputter Time | 20sec, 40sec, 60sec (3steps) |

Vacuum Pump | 100L/min, Rotary Pump |

Power | 220VAC ±10%, 50/60Hz |

Dimension | Main : 380(W)x240(D)x235(H)mm, 10kg |