The Alpha-Step D-500 stylus profiler is capable of 2D step height measurement from a few nanometers up to 1200µm. The D-500 also supports 2D measurements of roughness, bow and stress for R&D and production environments. The D-500 stylus profilometer includes a manual 140mm stage and advanced optics with enhanced video controls.

he innovative optical lever sensor technology offers high resolution measurements, large vertical range and low force measurement capability.

An advantage of the profilometer's stylus measurement technique is that it is a direct measurement, independent of material properties. Adjustable force and choice of stylus enable accurate measurements of a wide variety of structures and materials. This enables quantification of your process to determine the amount of material added or removed, plus any changes in structure by measuring roughness and stress.

Designed for universities, research labs and institutes, the Alpha-Step provides step height, roughness, and stress metrology for semiconductor and compound semiconductor devices, LEDs, solar, MEMS, automotive and medical devices.

Files

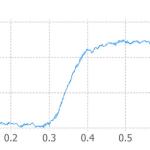

Step Height

The Alpha-Step D-500 stylus profiler is capable of measuring 2D step heights from nanometers to 1200µm. This step height measurement enables quantification of material deposited or removed during etch, sputter, SIMS, deposition, spin coatings, CMP and other processes. The Alpha-Step series has low force capability that enables measurement of soft materials, such as photoresist.

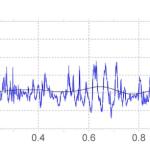

Texture: Roughness and Waviness

The Alpha-Step D-500 measures 2D texture, quantifying the sample's roughness and waviness. Software filters separate the measurement into the roughness and waviness components and calculate parameters such as root mean square (RMS) roughness.

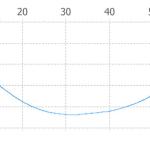

Form: Bow and Shape

The Alpha-Step D-500 can measure the 2D shape or bow of a surface. This includes the measurement of wafer bow that can result from mismatch between layers during the device fabrication, such as the deposition of multiple layers for the production of semiconductor or compound semiconductor devices. The D-500 can also quantify the height and radius of curvature of structures, such as a lens.

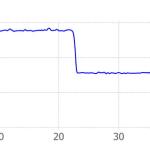

Stress: 2D Thin Film Stress

The Alpha-Step D-500 is capable of measuring stress induced during the manufacture of devices with multiple process layers, such as semiconductor or compound semiconductor devices. The bow of the sample is accurately measured using a stress chuck to support the sample in a neutral position. The change in shape from a process such as film deposition is then used to calculate the stress by applying Stoney’s equation.

The options for the Alpha-Step® D-500 Stylus Profiler are available to add on with your new product, or in the future

Stylus Options

The Alpha-Step D-500 has a variety of styli available to support the measurement of step heights, high aspect ratio steps, roughness, sample bow, and stress. The tip radius ranges from 100nm to 50µm and determines the lateral resolution of the measurement. The included angle ranges from 20 to 100 degrees, which specifies the maximum aspect ratio of the measured feature. All styli are manufactured from diamond to reduce wear and increase stylus lifetime.

Sample Chucks

The Alpha-Step D-500 has a range of chucks available to support application requirements. The standard chuck is a nickel-plated aluminum chuck for samples up to 140mm. A flat black chuck is available for transparent samples to minimize reflection from the chuck surface. A universal vacuum chuck is also offered and includes precision locating pins for samples from 50mm to 125mm. Both the standard and universal chucks support stress measurements with 3-point locators to hold the sample in a neutral position for accurate bow measurements.

Isolation Tables

The Alpha-Step D-500 has both tabletop and free-standing isolation table options. The Granite Isolator™ Series offers tabletop isolation systems that combine granite with high grade silicone gel to provide passive isolation. The Onyx Series tabletop isolation systems use pneumatic air isolators to provide passive isolation. The TMC 63-500 Series isolation table is a free-standing steel frame table that uses pneumatic air isolators to provide passive isolation.

Step Height Standards

The Alpha-Step D-500 uses thin and thick film NIST traceable step height standards offered by VLSI Standards. The standards feature an oxide step on a silicon die mounted on a quartz block. A step height range of 8nm to 250µm is available.

Apex Analysis Software

Apex analysis software enhances the standard data analysis capability of the D-500 with an extended suite of leveling, filtering, step height, roughness, and surface topography analysis techniques. Apex supports ISO roughness calculation methods, plus local standards such as ASME. Apex can also serve as a report writing platform with the capability to add text, annotations, and pass/fail criteria. Apex is offered in eleven languages.

Offline Analysis Software

The Alpha-Step D-500 offline software has the same data analysis capability that exists on the tool. This enables the user to analyze data without using valuable tool time.

Technical Features

- Step Height: Nanometers to 1200µm

- Low Force: 0.03 to 15mg

- Video: 5MP high-resolution color camera

- Keystone Correction: Removes distortion due to side view optics

- Arc Correction: Removes error due to arc motion of the stylus

- Compact Size: Smallest system footprint for a benchtop stylus profiler

- Software: User friendly software interface