The DPX M2000 is an advanced digital microscope designed to meet the needs of professionals and researchers who require exceptional performance and precision in their analyses. With a sophisticated design and advanced features, the DPX M2000 is the ideal choice for applications in laboratories, research institutions, industrial sectors, and education.

Key Features:

-

Ultra-High Resolution Imaging: The DPX M2000 is equipped with a state-of-the-art digital camera that allows for incredibly sharp and detailed images. This makes it perfect for precision microscopic analysis, enabling the observation of even the smallest details with clarity.

-

Complete Manual Control: The manual operation gives users full control over sample positioning and focusing, making the observation process highly precise and customizable to meet any needs.

-

Versatility and Diverse Applications: This microscope is ideal for a wide range of applications, from material analysis and biological research to education and industrial monitoring. Its versatility makes it an indispensable tool in many fields.

-

Compatibility with Advanced Software: The DPX M2000 is compatible with professional software for image processing and analysis, allowing users to perform calculations, measurements, and generate reports quickly and efficiently. Acquired images can be easily exported for further processing.

-

Robust and Compact Design: Thanks to its solid and compact structure, the DPX M2000 is easy to transport while remaining highly durable. This makes it perfect for dynamic environments and situations requiring high mobility.

Why Choose the DPX M2000?

The DPX M2000 is the perfect choice for those seeking a digital microscope that combines high image quality, ease of use, and a highly versatile design. Its ability to provide precise and detailed images, along with its compatibility with advanced software, makes it an essential tool for those working in scientific, industrial, and educational settings.

Whether conducting in-depth research in the laboratory, engaging in educational activities, or monitoring industrial processes, the DPX M2000 is designed to deliver reliable results and superior performance in any situation.

Contact us to discover how the DPX M2000 can improve your work and support your analyses. We are here to provide all the necessary information!

Files

| Attachment | Size |

|---|---|

| 8.07 MB |

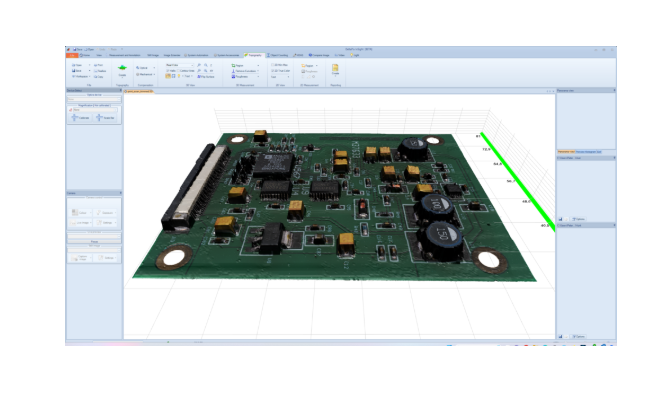

Comprehensive and intuitive 3D measurements. The DPX M2000 system is a fully capable 3D, surface analysis, and measurement system. 2D parameters like angle, distance, and area can easily be visualized and measured in 3D. Traditional 3D systems like confocal and scanning microscopes can struggle with complex surface topography, but, the DeltaPix DPX M2000 systems, display all complex details in true color. The 3D capabilities are also available in the XY-scanning mode, so detailed 3D images can be captured automatically at pre-saved XYZ-positions for later analysis.

DeltaPix InSight can be applied to measure the height parameters for the roughness surface and the waviness surface, along with the volume parameters, thereby avoiding the need for third-party applications for most texture analysis. The surface texture analysis can also be performed on extracted profiles according to ISO 4287. DeltaPix InSight can level the data and remove form by fitting a plane, sphere, cylinder, or polynomial to the topography. Gaussian, Double Gaussian, and Robust Gaussian filters are available to extract the roughness and waviness data. The results can be exported to an Excel spreadsheet.

The DPX M2000 is the perfect solution for inspecting large sample areas and identifying particles and imperfections. The software can automatically scan large areas, for example, an A4 page*1, and count, separate, and analyze all particles in the area with sizes down to less than 5µm. Based on the result, it can generate a report including number of particles grouped by size, form, and orientation. It can even set up an automatic approved/not approved range. This can be made according to ISO 16232/VDA 19 standard