The key strength of Regemat3D lies in its customization: each printer is handmade, making it highly adaptable to the specific needs of individual laboratories.

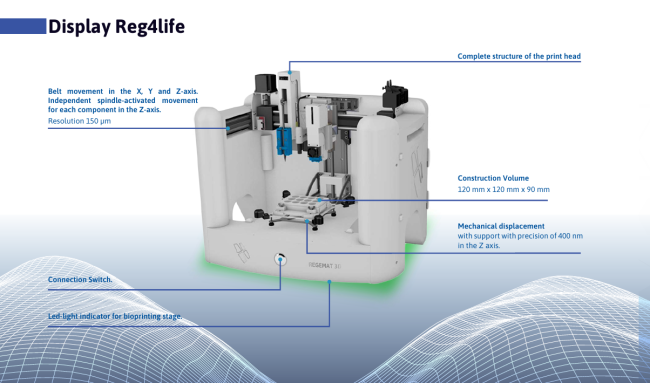

The configuration of the print head and the wide range of independent movements in X, Y, and Z allow precise system adjustments and enable printing on various surfaces, such as glass, Petri dishes, or multi-well plates with 6, 24, or 96 wells.

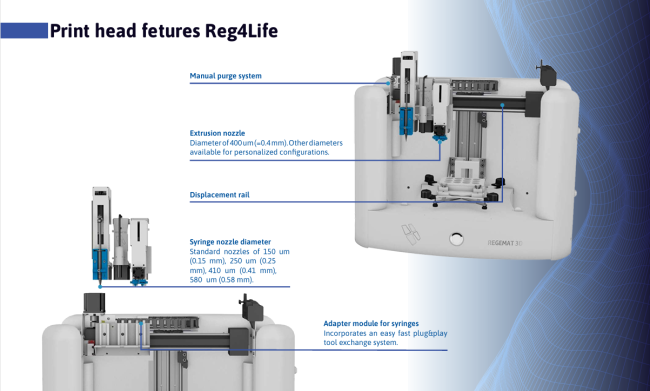

Mechanical extrusion, as opposed to pneumatic extrusion, ensures better resolution: with this technology, material retraction is possible, increasing precision, and a more uniform and homogeneous flow can be achieved.

The calibration of the print head is fully automated thanks to an accurate laser positioning system.

The equipment includes a set of print heads with variable extrusion diameters (0.15 mm, 0.58 mm, 1.20 mm) that can be easily swapped using a Plug&Play system, along with a support unit. The syringes can feature a dual thermoplastic extruder for printing scaffolds with two different thermoplastic materials simultaneously, a specific tip for biological compounds, heating or cooling capabilities, or a concentric extruder to create an internal structure surrounded by an outer perimeter of a different material. The temperature range for the syringes is from -20°C to 250°C, while the support unit ranges from 0°C to 120°C. For the photopolymerization of biomaterials, ultraviolet, infrared, and blue lights are available.

The actual resolution in XY is 150 μm, while in Z it is 400 nm.

The system includes a compartment designed for the installation of thermoplastic rolls. An LED lighting system allows for visual verification of the printing process in addition to software monitoring.

The ergonomic design and lightweight construction of the device make it easy to transport and use inside flow cabinets: the Reg4Life system is designed with dimensions that allow it to fit into any cabinet. Additionally, its base design with longitudinal openings facilitates laminar flow for sterilization.

The main applications of this technology include tissue regeneration for skin, bone, cartilage, cardiac tissue, and cornea, as well as tumor models, drug testing, biomaterials development, and personalized treatments (Lab-on-a-chip kits, Organ-on-a-chip).

Videos

News, events, promotions, webinars

Technical Features

Resolution

- Resolution real in the X e Y axis (spindel movement) = 150 μm (0.15mm) | Resolution in Z = 400 nm (0,4 microns)

- Theoretical resolution in the X and Y axis = 1.875 micras - 1875 nm

- Thermoplastic extruder Nozzle output diameter 0,4 mm.

- Syringes: Several output diameters 0,15 mm, 0,58 mm, 1,20 mm

Bioprinting Applications

- Tissue regeneration:

- Skin - Bone

- Cartilage - Cardiac tissue

- Cornea - Tumoral models

- Drug testing

- Biomaterials development

- Personalising treatment: Lab on a chip kit / Organ on a chip

Temperature Control

- Thermoplastic Extruder:

- Filament (Until 250ºC)

- Pellet

- Biomaterials extrusión (through syringes):

- -20 until 100 grades

- Biomaterials light-curing:

- Ultraviolet light

- Infrared light

- Blue light